Is Mori Seiki Same As Dmg Mori

- Dmg Mori Seiki Parts Distributors

- Is Mori Seiki Same As Dmg Mori Movie

- Is Mori Seiki Same As Dmg Mori Free

- Dmg Mori Seiki Co

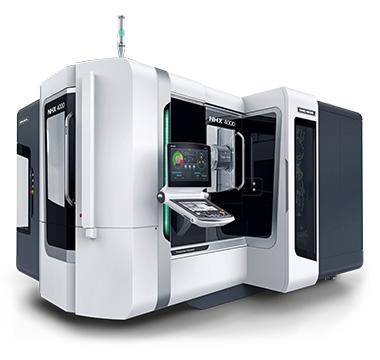

DMG MORI offers a unique range of machine tools of several sizes. Browse DMG MORI used machines – one of the largest manufacturers of metal cutting machines.

DMG MORI uses cookies to ensure you the best experience on our website. When you browse the website you agree to our use of cookies. More information on data protection and revocation. More On Mori/DMG Web Site For Other Specifications.Shipping is the responsibility of Buyer- Unit will be prepped according to the manufacturer and buyer to schedule pick up and load.All costs associated with shipment are buyers responsibility Unit sold'AS IS' Absolutely No Returns- Please ask all questions or schedule to view prior to. Established MORI SEIKI U.S.A., INC. (current DMG MORI U.S.A., INC.) Started actual operation at Iga No.1 Plant. The Company was transferred to the first section of the Tokyo Stock Exchange and Osaka Securities Exchange. DMG MORI employees are the best in their field. Their experience, expertise and dedication to the machine tool industry make DMG MORI the company it is. In return, we provide growth opportunities, industry-leading benefits and a work environment that fosters creativity and leadership.

DMG MORI Original Spare Parts We offer you a availability rate on spare parts through all DMG MORI technology sectors of more than 95%. Whenever and whatever you need, with DMG MORI you‘re on the safe side. The DMQP program is designed to certify peripherals that meet DMG MORI standards in quality, performance and maintainability. DMQP provides customers with even greater peace of mind. On 8 June 2015, DMG MORI Seiki Aktiengesellschaft became DMG MORI Aktiengesellschaft and DMG MORI Seiki Company Limited changed its name to DMG MORI Company Limited as a further confirmation of the merger.

Products include innovative high-tech CNC machines such as lathes, milling machines, advanced technologies (ULTRASONIC / LASERTEC) as well as Software Solutions and Systems. Industrial services include a wide range of services in relation to the entire machine lifetime, used machines, accessories and energy solutions. All turning machines, machining centers and automatic turning centers are based on a modular kit of hightech components.

Increase your productivity with machine tools from DMG MORI.

Dmg Mori Seiki Parts Distributors

Browse our current inventory below:

You'll find a wide selection of our DMG MORI used machines below. Click on a specific DMG MORI used machine's listing for details or request a quote. If you don’t see a specific machine or model you are interested in, let us know, and our team will track down the equipment you need.

This was the technology highlight this year at the company’s Open House exhibition held in February in Germany, while further global expansion plans were revealed.

Playstyle for Affliction Warlock. Affliction Warlocks aim to apply a series of damage over time effects to targets, weaving in empowerments and buffing them up where possible. Much of the optimization revolves around maintaining your active effects while ensuring you spend Soul Shards correctly. Aug 15, 2015 If you want Aff as your single target spec you need to use your 2nd spec for any AoE fights, Demo is usually the best option for this. If you don't want to keep changing specs every fight then go Destro, it currently has the best single target (but iirc requires good gear) and doesn't do too badly on AoE fights due to shadowburn sniping.

Playstyle for Affliction Warlock. Affliction Warlocks aim to apply a series of damage over time effects to targets, weaving in empowerments and buffing them up where possible. Much of the optimization revolves around maintaining your active effects while ensuring you spend Soul Shards correctly. Aug 15, 2015 If you want Aff as your single target spec you need to use your 2nd spec for any AoE fights, Demo is usually the best option for this. If you don't want to keep changing specs every fight then go Destro, it currently has the best single target (but iirc requires good gear) and doesn't do too badly on AoE fights due to shadowburn sniping.

DMG Mori is the combined sales and service operation for the currently separate firms of DMG Mori Seiki Co, Japan (formerly Mori Seiki Co) and DMG Mori Seiki AG, Germany (formerly Gildemeister AG), reports Andrew Allcock, Editor of Machinery UK. The two companies have been working together across sales, service, development, production, purchasing and finance since March 2009. There is already a cross-shareholding between the two, but they will become a single company in 2020, as announced in October last year.

Is Mori Seiki Same As Dmg Mori Movie

With the Lasertec 65 Additive Manufacturing, DMG MORI presents a machine, which is currently unique and incorporates laser deposition welding into a fully-fledged 5-axis milling machine

Combined sales for the two global machine tool makers are over £2.5 billion (DMG Mori Seiki AG, €2 billion/£1.645 billion [to 31/12/2012]; DMG Mori Seiki Co, ¥150 billion/£884 million [to 31/3/2013]), while their combined production capacity is put at 20 000 machines a year.

World standing

So, by volume, that puts the couple ahead of Haas Automation, which claims the position of the largest producer of CNC machine tools in the Western world; and by value puts them ahead of Japan’s Yamazaki Mazak, which claims the position of “the world’s largest producer of CNC metalcutting machine tools”, (sales over €1.5 billion/£1.23 billion).

The DMG Mori Seiki AG turnover figure includes its energy products activity, so its machine tools’ revenue is lower than the headline figure, at €1.175 billion/£966 million but services related to machine tools are put at €790.5 million/£650 million, so, on combining these figures, the Yamazaki Mazak claim could be challenged, although DMG Mori Seiki AG makes no such challenge. Overall employee count for DMG Mori Seiki AG and DMG Mori Seiki Co is 10 400, with DMG Mori boasting 500 employees.

Generative manufacturing

The unmistakable overall message is that the two companies together are a major global force in the machine tool industry. Across the world, there are almost 500 DMG Mori machine tools in some 100 DMG Mori showrooms, staffed by the 500 employees, while there are also 50 technology partners.

The two companies have a combined product offering of around 200 machine models, although rationalisation to around 100 models is on the cards, with these machines produced at 19 machine tool manufacturing sites worldwide.

And with an R&D workforce approaching 1 000 engineers, the frequent announcement of new products is a habit that only gathers pace, with the February Pfronten, Bavaria, Germany Open House a major fixture on the calendar. Eight world premières were unveiled to an audience of 6,000+ visitors. And they “come to learn what’s new from DMG Mori, what innovations we have to offer”, says Mori Seiki AG chairman of the board Dr Ruediger Kapitza.

Sauer Lasertec 65 Additive Manufacturing

The technological highlight this year was the Sauer Lasertec 65 Additive Manufacturing, a machine that combines traditional milling/toolchanging with additive manufacturing in the frame of a DMU 65 monoBLOCK machining centre. A development from DMG Mori Seiki AG company Sauer AG, the machine offers a unique proposition – the ability to create solids from powder and then machine them to the finished state.

First revealed at Euromold last December, the Lasertec 65 incorporates a 2 kW diode laser system (glass fibre optic-transported beam), located to the right in the working envelope. Build rate, at 3.5 kg/hour, is 20x faster than for powder bed machines. Wall thicknesses of 0.1 mm to 5 mm can be built up, depending on the laser and the nozzle geometry, while complex 3D contours can also be generated in layers, without the need for supports. The machine’s capacity is 650 mm diameter by 360 mm in height, with a maximum weight of 1,000 kg.

Repair

The laser head features an HSK back end, with the spindle picking it up from its location, which is currently within the working envelope. The use of a powder nozzle additive manufacturing system allows for a faster material build-up versus powder bed machines (which cannot machine), while such technology is “easily implemented within a machine tool”, according to Friedmann Lell, Sauer GmbH sales director. Indeed, the technology could be incorporated into any number of DMG Mori machine tools.

Is Mori Seiki Same As Dmg Mori Free

At the Pfronten Open House, a funnel-shaped part was shown being produced, via video. Approximately 150 mm high and 180 mm diameter at its widest end, it features annular spigots around the funnel’s external wall and also has two flanged ends featuring drilled holes. Built from nothing using stainless steel powder and then fully machined, it takes some about five hours. The same part would take around 50 hours, using a powder bed machine, would need support structures added during build and, of course, would not be finished machined.

The machine on show at Pfronten was a ‘project’ – a functional study – not the finished machine. Currently only dry machining is possible, as the laser is not fully protected, but the final design will support coolant use, with full protection for the laser. That machine will be available around the middle of the year and will break cover at the IMTS 2014 (Chicago, USA) and then AMB (Stuttgart, Germany) exhibitions. And Mr Lell says that five machines will be shipped this year. Unsurprisingly, the machine price is not yet fixed.

While a machine such as this could have been developed some years back, the reason for its development now is customer demand. There is no additive machine currently available that offers the surface quality and component accuracy that DMG cutting machines do: “So we developed an additive manufacturing machine for our customers that does give such quality and accuracy.” And there is “unbelievable interest”, with this emanating from Europe and the USA, Mr Lell offers.

Regarding the temperature of the additively produced features, if highest machined accuracy is required, then cooling must take place prior to cutting – the application of coolant to accelerate that process is a possibility, he says.

As for material properties, currently stainless steel is the trial material. “We are not finding any porosity,” Mr Lell says, but adds that the company “is not yet the process expert”.

Inconel and aluminium

The next material to be tested will be Inconel, which has long been used in additive manufacturing, so should present little problem, he suggests. Following that, aluminium is the next material on the agenda, but this does present greater challenges regarding porosity, so will require greater process development.

For the project machine, CNC programs are being generated via two systems: one for the additive element of the process and another for the cutting element. At the launch of the production unit this year, there will be a single software system for programming, Mr Lell says, with the machine itself using Siemens CNC only.

Coating

As to the matter of process control/repeatability and consistency of component quality/performance, this will require further machine development. At the moment there is no process control. “For aerospace turbine or aircraft parts, if you make 1 000 parts, how do you avoid any failures? This is an open question. There will be process monitoring in the future, with many parameters involved. But there are many parts today that do not require this level of control,” Sauer’s sales director explains. It’s the same situation for powder bed machines, of course, although there are efforts in this area under way already.

Dmg Mori Seiki Co

And the market for its Lasertec 65 Additive Manufacturing? Well, around 100 metal AM powder bed machines are sold annually. This is the first time a machine dedicated to manufacturing has been developed, so it’s a new market. Its launch will “definitely give a push to the market” with its potential “tremendous”, Mr Lell concludes.